-40%

Vinyl Flake Chip Epoxy Concrete Garage Floor Paint Coating Pigment Kit

$ 5.27

- Description

- Size Guide

Description

Here are the components needed to do a project:1) Epoxy Crack Repair ( As needed). Note: Epoxy paint will fill small cracks up to 1 mm wide. Use Crack Repair for larger cracks.

2) Primer - Use White or Clear for lighter color finishes and Black for darker colored finishes.

*3) Epoxy Pigment - Use to color the Epoxy Base.

4) Epoxy Base - Mix Part A with Pigment first and then with Part B (Hardener). Use as primary floor coating.

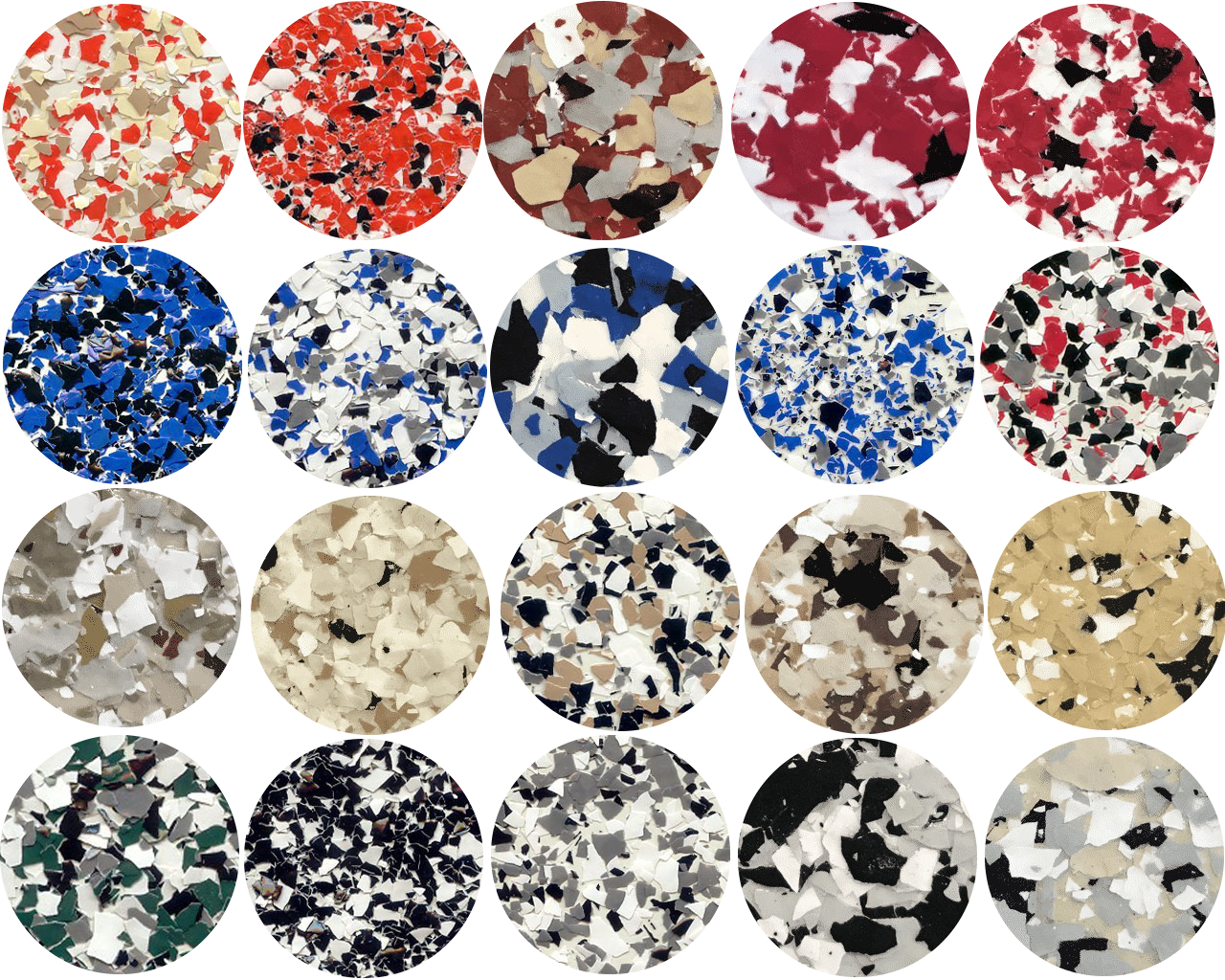

5) Vinyl Flakes - Broadcast into Epoxy.

6) Urethane Clear Top Coat (Optional)

*Note on Pigment & Flakes: If you buy pigment or flakes, please be sure to include your color/blend choices in the notes section along with your payment. We will not ship until we know what color pigments and flakes you want.

Coverage Table (Note- Most "kits" being sold by others scrimp on materials and overstate coverage. We recommend minimum of 9 mils of epoxy which will be 150ft2 per gallon. Before you buy another "kit", make sure you know how many gallons of epoxy you are getting. Also, make sure you are getting 100% solids epoxy):

Product

Amount

*Coverage is dependent on how thick you apply the coating. These coverages are based on the following thicknesses:

Epoxy Crack Fill

1 Gallon

As Needed. Depends on how many and how large your cracks are.

Primer

1.25 Gallons

Three (3) mil dry film 300 sqft. Six (6) mil dry film 150 sqft.

Primer

5 Gallons

Three (3) mil dry film 1500 sqft. Six (6) mil dry film 750 sqft.

Epoxy Base Pigment

1 Packet

Enough to mix with 1.5 Gallons of epoxy

Vinyl Flakes

1 Pound

Each pound of flakes will cover between 75 = 250 ft2. Light Broadcast = 1 pound of flakes/250 ft2. Heavy broadcast will require 5 pounds of flakes for 250 ft2

.

Epoxy

1/2 Gallon

1/2 Gallon will cover between 75sqft (9mils) and 125 sqft (5mils)

Epoxy

1 Gallon

1 Gallon will cover between 150sqft (9mils) and 250 sqft (5mils)

Epoxy

2 Gallons

2 Gallons will cover between 300sqft (9mils) and 500 sqft (5mils)

Epoxy

3 Gallons

3 Gallons will cover between 450sqft (9mils) and 750 sqft (5mils)

Epoxy

5 Gallons

5 Gallons will cover between 750sqft (9mils) and 1250 sqft (5mils)

Epoxy

15 Gallons

15 Gallons will cover between 2250sqft (9mils) and 3750 sqft (5mils)

*Urethane 7% VOC

1 Gallon

250sqft(6mils When Dry)-500sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (500SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (250SF/gal).]

*Urethane 7% VOC

1-1/2 Gallons

375sqft(6mils When Dry)-750sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (500SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (250SF/gal).]

*Urethane 7% VOC

15 Gallons

3750sqft(6mils When Dry)-7500sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (500SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (250SF/gal).]

**Urethane 50% VOC

1 Gallon

125sqft(6mils When Dry)-250sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (250SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (125SF/gal).]

**Urethane 50% VOC

1-1/2 Gallons

187sqft(6mils When Dry)-375sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (250SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (125SF/gal).]

**Urethane 50% VOC

15 Gallons

1875sqft(6mils When Dry)-3750sqft(3mils When Dry) [Based on 3 mil (Dry) thick (When Dry) single coat (250SF/gal). Based on 6 mil (Dry) thick (When Dry) single coat (125SF/gal).]

Epoxy Thickening Agent

1 Gallon

Add 1 gallon of Epoxy Thickening Agent to each 1-3 gallons of Epoxy (Depending on how thick you want the epoxy)

7% VOC = 0.79 Lbs/Gallon (Volatile Organic Content)

50% VOC = 3.8 Lbs/Gallon (Volatile Organic Content)

**Note: mil thickness reduces when it dries. Always compare wet versus dry mil thickness.

Components:1/ Crack Repair (As Needed) 2/Primer 3/ Epoxy Base 4/ Epoxy Pigments 5/ Vinyl Flakes 6/ High Wear Urethane Top-Coat (Optional)

1) Crack Repair

Crack Repair Patch is a two-component, modified epoxy. It is the ideal product for patching concrete cracks, spalled areas and small holes (<1”) after surface preparation

has been completed. Its extreme physical properties and high load-bearing strength makes Epoxy Crack Repair Patch the ideal product for filling and patching prior to the application of all Epoxy systems. Epoxy Crack Repair Patch is specially formulated to dry in 60 minutes, so you can complete crack repair and epoxy coating in 1 day.

2) Primer

Premium quality 2-component water base epoxy concrete sealer/primer that provides epoxy toughness, chemical resistance and durability with the convenience of a water base VOC free system. Available in clear white or black. Use clear for sealing concrete to bring out the natural look. Use a black or white kit to seal your concrete with a solid color. If installing an Epoxy flooring system, we recommend using white for lighter final finishes and black for darker final finish to enhance the final look of the floor. Primer promotes better adhesion, helps to prevent pin holes and bubbles in the finish coat, and allows the finish coat to spread easier and better. We consider it essential.

3) Epoxy Color Pigments

Epoxy Color Pigments are special pigments composed of various organic and inorganic pigments to color the epoxy base coat.

4) Clear Two Part 100% Solids Epoxy Base

Epoxy base is a clear two component, high performance modified cycloaliphatic epoxy concrete floor coating system. Its epoxy chemistry provides excellent bonding characteristics. Its design features provide for the highest industrial and commercial demands. It can be applied as a 5 to 50 mil coating system. Epoxy Color Pigments can be mixed into it to create a custom base color. A key feature of this epoxy is its extended working time. With up to 45 minutes of working time, it allows both the experienced contractor and the first time do-it-yourselfer enough time to create stunning one of a kind floors without having to worry about the clock. It offers extended working time even in hot and humid environments.

5) Vinyl flakes can be broadcast into the epoxy base coat before it dries. Flakes can be spread as thick or ans thin as you desire. See images for examples and coverages.

6) Urethane Three Part clear top coat.

A three component aliphatic urethane floor finish that exhibits excellent characteristics for abrasion resistance, chemical resistance, flexibility, weathering and UV stability. For auto service centers, warehouses, computer rooms, laboratories, aircraft hangers, cafeterias, indoor or outdoor service, chemical exposure areas, restaurants, retail and commercial spaces, offices and residential. For a gloss finish combine part a and b. For a satin finish add the included part c.

Mixing:

Crack Repair:

Mix equal parts A and B using a putty knife or spatula.

Primer:

Primer has a mix ratio of 4:2:1 (4 parts A to 1 part B and 2 parts water). MIX 4 PARTS "A" WITH 1 PART "B" IN BATCHES NO LARGER THAN 1.25 GALLON AT A TIME . In a clean and dry bucket, mix 4 parts A and 1 part B together using an agitator, jiffy mixer or mixing paddle and drill . Mix slowly for at least 2 minutes or until completely combined. Add 64 oz. of cold water to blended Parts A & B. Mix for another 2 minutes. Prepare only the amount you can use in 2 hours in quantities of no more than 1 .25 gallon (1.75 with addition of water) at a time. Do not leave the mixed epoxy in the bucket longer than 3 hours. Once you mix the two parts of the epoxy, you only have about 2 hours of working time, so plan your batch sizes accordingly.

Epoxy and Pigments:

Smaller Kits (Note Smaller kits come with 1:1 ratio Epoxy - Check and use the proper ratio printed on the containers):

Ratio: 1/2 gallons of Part A to 1/2 Gallon of Part B to 4-5 ounces of Pigment. Smaller batches can be mixed, but maintain the proper ratio. The pigment can be mixed into either part. However, since Part A is thinner, most find it easier to mix the Pigment in the A part. Pigments can be added and mixed into part A prior to mixing the part A and B epoxy together and that can be stored, but make sure the lid is securely sealed after mixing. To ensure thorough mixing of the pigment we recommend mixing the pigment for 10 minutes per kit with an electric drill and mixing paddle. ***IMPORTANT - MIX THOUROUGHLY AND ACCURATELY TO AVOID AREAS/POCKETS OF TACKY/UNCURED EPOXY*** Once you mix the two parts of the epoxy, you only have about 45 minutes of working time, so plan your batch sizes accordingly.

Larger Kits (Note Most larger kits come with 2:1 ratio Epoxy - Check and use the proper ratio printed on the containers):

Ratio: 2 gallons of Part A to 1 Gallon of part B to 12-16 ounces of Pigment. Smaller batches can be mixed, but maintain the proper ratio. The pigment can be mixed into either part. However, since there is twice as much part A as part B, most find it easier to mix the Pigment in the A part. Pigments can be added and mixed into part A prior to mixing the part A and B epoxy together and that can be stored, but make sure the lid is securely sealed after mixing. To ensure thorough mixing of the pigment we recommend mixing the pigment for 10 minutes per kit with an electric drill and mixing paddle. ***IMPORTANT - MIX THOUROUGHLY AND ACCURATELY TO AVOID AREAS/POCKETS OF TACKY/UNCURED EPOXY*** Our 3 gallon kits are packaged in a convenient metal 5 gal pail. When you open the lid you will see the 1 gallon can of part B in a plastic cradle. The 2 gallons of part A are at the bottom of the pail. Once you mix the two parts of the epoxy, you only have about 45 minutes of working time, so plan your batch sizes accordingly.

Urethane:

For a gloss finish combine part a and b. For a satin finish add the included part c. To ensure thorough mixing of the pigment we recommend mixing for 10 minutes per batch with an electric drill and mixing paddle. Once you mix the, you only have about 45 minutes of working time, so plan your batch sizes accordingly. ***IMPORTANT - MIX THOUROUGHLY AND ACCURATELY TO AVOID AREAS/POCKETS OF TACKY/UNCURED URETHANE***

Coverage:

See Table Above

Application:

Primer:

Application should be made with a non shed 3/8 nap roller. Edge trim using a brush. We recommend an 18" roller for faster and more even coverage. The mixed material can be applied using a paint tray, can be squeegeed and backrolled, or can be poured in small amounts to the concrete surface and then squeegeed and then rolled into place.

Epoxy Base:

Application should be made with a non shed 3/8 nap roller. Edge trim using a brush. We recommend an 18" roller for faster and more even coverage. The mixed material can be applied using a paint tray, can be squeegeed and backrolled, or can be poured in small amounts directly onto the concrete surface and then rolled into place.

Urethane:

Application should be made with a non shed 3/8 nap roller. Edge trim using a brush. We recommend an 18" roller for faster and more even coverage. The mixed material can be applied using a paint tray, can be squeegeed and backrolled, or can be poured in small amounts directly onto the concrete surface and then squeegeed then rolled into place.

Color Charts for Epoxy Base Coat Color Pigments:

(Note- If you buy pigment or flakes, please be sure to include your color/blend choices in the notes section along with your payment. We will not ship pigments or flakes until we know what color pigments you want.)

Floor Applications: Note - These results are achieved using these general basic steps:

Step 1: Clean and prepare surface and then apply primer. Let primer dry overnight.

Step 2: Mix and apply Epoxy Base by pouring the base color onto the floor. Spread evenly with squeegee and then lightly roller to level paint.

Step 3 : Spread vinyl flakes over the surface to create speckled appearance as desired.

Step 4: Allow Epoxy to dry overnight.

Step 5: Apply Urethane top coat (optional). Do not wait more than 24 hours to apply Urethane.

With a little creativity and effort, these incredible results are relatively easy to achieve, however results are not guaranteed. I am offering these products and tips as a service for those who want professional results without spending thousands of dollars.

******Biggest mistakes made: Not mixing the 2 parts thoroughly/accurate proportions. Forgetting to add parts A and B together. This results in a sticky floor that will not cure.

EBAY POLICY: Ebay will not allow me to post links to videos. If you make a purchase and want to watch a how-to video, email me with your email address and I will send you a link to videos. Ebay will not allow me to share a phone number or email address, until after a purchase is made.

Please do not ask me for contact information before you make a purchase

These are 1/4" Flake Blends (Click Image to Enlarge):

These are 1/8" Flake Blends (Click Image to Enlarge):

These are 1/4" Flake Solid Colors for Making your Own Custom Blends:

Supplies

18" x 3/3" Nap Lint Free Roller Cover

12-18" Adjustable Roller Holder

4" Power Mixer for mixing all paints and epoxies. * Use in 1 & 5 Gallon...

18" Serrated Squeegee Head Only

Black Spike Shoes. 3/4" spikes. The 13 spikes are configured in the foot bed to provide maximum balance and prevent toe-tipping. One size fits all. This allows the applicator to walk on the wet epoxy.

(Note: Spikes can come loose during transit: Please Tighten Spikes before using)

Etch 'n Clean (Use to Prep Floor Before Coating)

Concrete floors require preparation before applying a paint, high - performance coating system, stain or a concrete sealer. The preparation usually involves cleaning the surface to remove oil and other unwanted contaminants then "profiling" the concrete by etching with acid or by mechanical abrasion. If the concrete does not have heavy oil contamination, The Etch 'n Clean will provide both the cleaning and the profiling in one operation. For optimized performance, dilute the etch 'n clean in a 1 to 1 mix ratio with water. (1 gallon of etch 'n clean with 1 gallon of water). This will give you 2 gallons of solution to work with. (500+ sq/ft feet). If the concrete has been steel-trowelled, the surface will be very smooth. This finishing technique works fine cement particles to the surface creating a very hard, dense finish. Steel-trowelled floors may require multiple applications to achieve the desired profile.

Lemon Damp Mop Neutral pH Cleaner (Use to clean floor after it is coated)

Product Description: A super concentrated lemon scented neutral cleaner. Especially designed to clean epoxy and Urethane floor finishes, marble and granite. This no rinse cleaner can be used to clean any surface that is not harmed by water. Where to Use: any washable surface, appliances, furniture, concrete, painted walls, no wax floors, ceramic tile, marble, wood, countertops, waxed floors & granite Directions for Use: READ ENTIRE PRODUCT LABEL PRIOR TO USE Light Cleaning: 1 oz. per gallon of water. Medium to Heavy: 2 to 4 oz. per gallon of water. Auto Scrubbers: 1 to 2 oz. per gallon of water. Packaging & Other Information: Yellow liquid - lemon fragrance

Note: Using any product that does not have a neutral pH will break down floor finish. Eliminate the high cost of re-waxing by using the right floor cleaner: Lemon Damp Mop. Compatible with all our finishes.

Floorshine Polymer Finish (Use to coat & shine floor after it is coated with Urethane or Epoxy)

This 25% solids, metal crosslinked, polymer finish will make your floors look wet even when they are dry. Some of the benefits of using Floorshine are: • superior protection • durability • reparability • black mark & detergent resistant • ultra high gloss • water resistant • non buffable • non scuffing • self-leveling • use with or without sealer • slip resistant (exceeds ASTM standard D2047-82) • most suited to high traffic areas • performs exceptionally well with either spray buffing or high speed buffing • V.O.C. Compliant Where to use: epoxy floor finishes, vinyl & vinyl asbestos, asphalt tile, concrete, linoleum, urethane floor finishes, sealed terrazzo, rubber, composition tile, wood Directions for use: Apply a thin uniform coat of finish to floor with new rayon mop. Allow to dry approximately 30 minutes. We recommend applying 3 – 4 uniform coats in this manner. Never pour left over finish back into the container to avoid contamination. Coverage: 2,000 - 2,500 sq. ft per gallon For BEST results, after Floorshine is applied. The coating should only be cleaned with a Neutral PH cleaner. This will avoid hazing, and keep the cleaner from dissolving the wax finish.

Denatured Alcohol ( Quart)

This is used for effects.

MEK ( Quart)

This is used for effects and for clean up (Most Powerful Solvent)

Xylene ( Quart)

This is used for effects.

Epoxy Thickening Agent (1 Gallon - Add 1 Gallon of thickening agent to 1-3 gallons of epoxy.)

This is used for thickening the Epoxy for Vertical applications.